Surface Mount Technology (SMT)

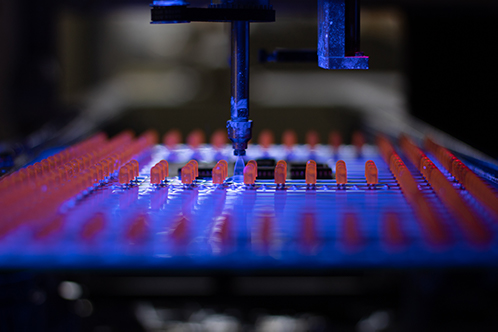

Each stage of the SMT soldering process is monitored and validated by control tools such as 3D Solder Paste Inspections (SPI) and Automatic Optical Inspection (AOI). The SPI checks the applied solder paste for volume, offset, height, positioning and thus plays a key role in quality assurance. 50% of PCBA failures are due to poor paste dispensing.

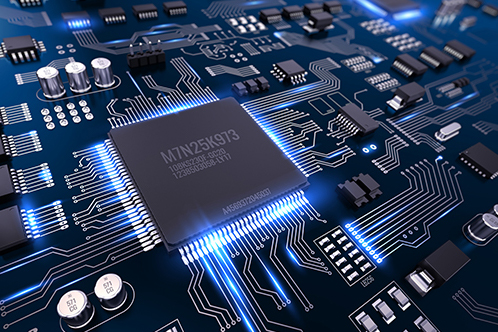

After P&P machines have assembled the components, the boards are checked again during an AOI. In this phase, the components, ranging from 01005 over fine pitch BGA to LGA - QFN - are checked for polarity, short circuits, solder quality, etc.